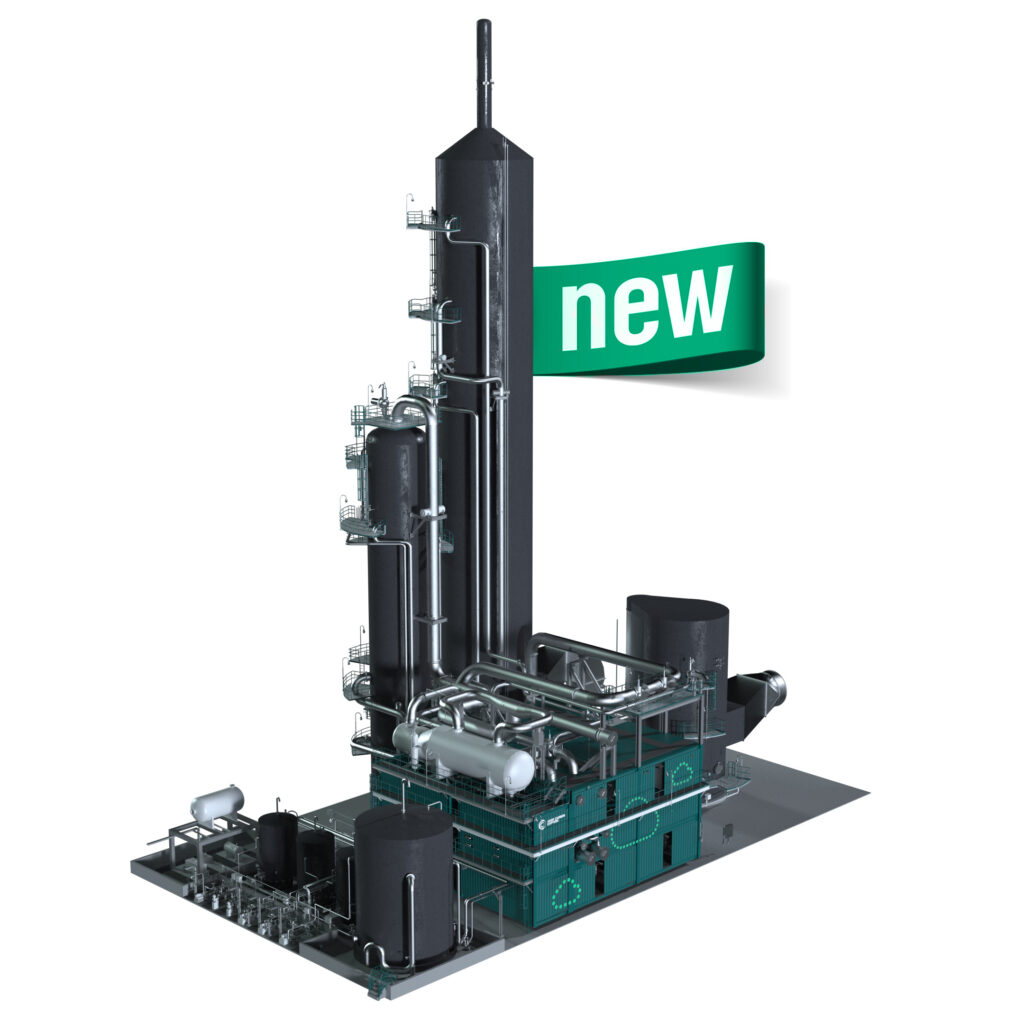

“Today is a very special day for us in Aker Carbon Capture”, says Chief Technology Officer Jim Stian Olsen. We are introducing the Just Catch™ 400 – a modular 400,000 tonnes capture unit – our latest addition to the Just Catch™ modular unit series.

Advanced Carbon Capture (ACC™)

Just outside Oslo, the beautiful capital of Norway, we find the Aker group headquarters with more than 4,000 engineers gathered at the campus. One of the companies, Aker Carbon Capture, has taken climate tech to a new level. For us, it started all the way back in early 2000, Olsen explains. The Aker group decided to develop process technology for capture of CO2 from flue gases, he explains. Collaborating with European industry as well as research institutions such as SINTEF and the Norwegian Technical University NTNU, it took more than 8 years and 45 researchers to develop the foundation of what is today the unique ACC™ process technology – Advanced Carbon Capture™. Tested and validated for 11 industrial applications and through more than 65,000 hours, few others can claim more experience with post-combustion carbon capture.

Modularity and scale

“By now, the European market has appreciated what the Advanced Carbon Capture™ process technology stands for”, Olsen explains. It is focused on energy efficiency and health, safety and environment (HSE) excellence, a differentiator when you realize carbon capture at scale”, he says. But the journey did not stop there. Aker Carbon Capture continued to address the key feedback in the market, and this gave way to the Just Catch™ modular plant series. Recently the 3rd generation Just Catch™ model 100 was introduced to the market, incorporating the learnings from delivering carbon capture units, such as at the waste-to-energy company Twence in the Netherlands. It featured an even smaller footprint, while opening for a much more spacious inside and an energy efficiency that earlier was only a feature in bigger plants.

Introducing the Just Catch™ 400

“With our three ongoing delivery projects in the Netherlands, Denmark and Norway, we wanted to take modularity to a new level, combining the speed and simplicity in delivery that modularity enables, together with an as built experience from our large Big Catch delivery at Heidelberg Materials Norcem Brevik CCS in Norway. At Brevik, we are delivering the world’s first large-scale carbon capture at a cement facility, with a capture capacity of 400,000 tonnes per year of CO2”, says Olsen. “The question we asked was – could we build the same into a modular plant with unique cost, risk and delivery improvements?”, Olsen asks. And that is exactly what Aker Carbon Capture has done, introducing the Just Catch™ 400.

An airline analogy

By Olsen’s side sits Zubin Mistry, the Head of Products and a key person behind the developments. “I think of the Just Catch™ 400 as similar to Boeing’s introduction of the 777 model – a model that can fit around 400 passengers”, he smiles. “It is a step up from Boing 737, which I think of as the Just Catch™ 100, our most popular model.” When asked how the model came together, he explains. “I saw my 2 daughters arguing over who would make a lego model they had been gifted. They agreed to complete 4 parts independently and then ask papa to help put them together. It seemed tricky to start with but things went so smoothly, I wondered if there was something I could learn from their idea. So I looked at the product the next day, tried to join the parts together and voila the 400 model was born”, Mistry explains.

“We had the vision of designing a modular plant that incorporates all the learnings from our ongoing delivery at Brevik and which is based on the Just Catch philosophy with ease of construction and deliverability. Listening to the market, we were convinced this would be something many emitters would appreciate. And inside the 30 x 55m that the capture unit entails, a lot of progress has happened”, says Mistry.

Just Connect Modularity™

“When the 3rd generation of Just Catch™ 100 was released, one of its highlights was how the modules allowed for more space inside while at the same time reducing the footprint of the total capture unit”, Zubin Mistry explains. -The secret behind it was a new connection system and how the modules came together like “lego”, achieved by high-quality engineering and fabrication with learnings from the Twence project in the Netherlands. In the Just Catch™ 400, we have taken this even further, introducing the Just Connect Modularity™ with unprecedented simplification of installation at site leading to a design which is not just more compact, but also even more agile across the units”, says Mistry. “This way we have reduced the size of the plant by 30%, compared to four Just Catch™ 100 units.

Just Catch™ 400

- Just Catch™ 400 Footprint 30×55

- Advanced Carbon Capture™ inside – Based on delivered components, proprietary solvent portfolio and experience from ongoing projects

- Just Connect Modularity™ – significant shorter installation time

- Can operate at 50% capacity with no increase in SRD

- Flexible capture capacity – 300-450 kTPA

- Delivered with a choice of the ACC Energy Saver™ or the ACC Heatconomizer™, both cutting edge advanced heat integration features

- Spacious operator friendly design

- Optimized for a number of industries

- And all the Just Catch™ benefits you love

- Short delivery time – 24-30 months

- Modules transportable by road

- Up to 95% capture rate

And all the Just Catch™ benefits you love

- Short delivery time – 24-30 months

- Modules transportable by road

- Up to 95% capture rate