Big Catch™

Proven. Cost effective. Modular.

>400.000

TPA capacity30-36 months

Delivery timeCustomized

footprint

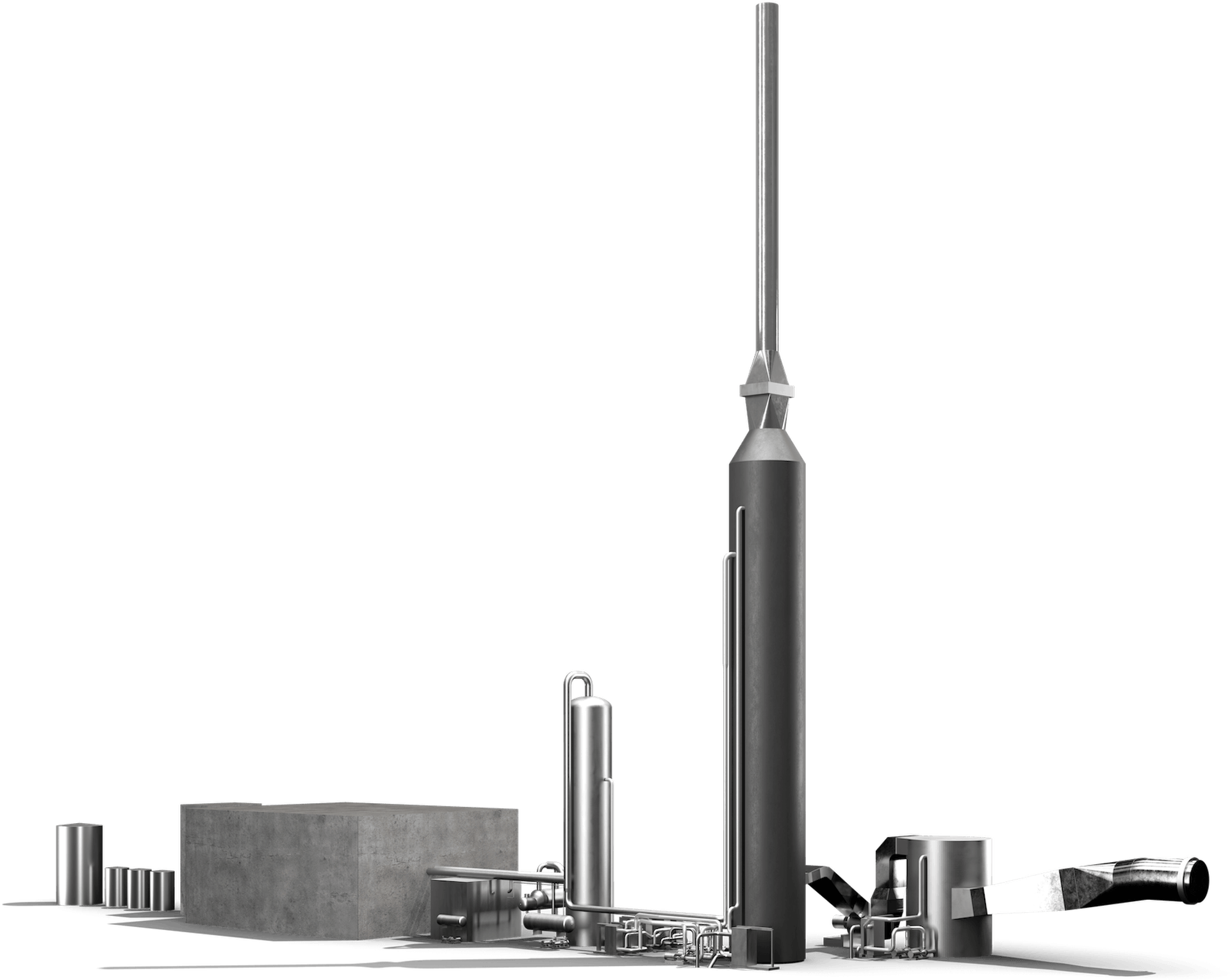

Big Catch™ design

We design and deliver both medium and large-scale industrial carbon capture plants, called Big Catch™. The large-scale industrial carbon capture plants are custom-made and cover capacities > 400 000 TPA into the millions. All our plants are based on the Advanced Carbon Capture™ process technology and the proprietary solvent portfolio.

Integration

Big Catch plants are fully integrated into the plants of our customers. This includes both advanced heat integration, and downstream integration enabling record low energy consumption by making it possible to reuse energy along the value chain. One example of this is our proprietary heat integration developed together with MAN Energy, which is being delivered as part of the world’s first carbon capture plant at a cement production facility at Brevik CCS in Norway.

Proven

Big Catch customers benefit from more than 20 years of technology development, including the scaling from our mobile test unit and up to large scale when we designed and delivered the Technology Center Mongstad (TCM) plant already in 2012. Today, Heidelberg Cement NORCEM is our customer for the EPC delivery that Aker Carbon Capture is undertaking in the Brevik CCS project which includes the capture unit, liquefaction, pipeline and intermediate storage on the quayside.

Specifications

- Capacity: > 400,000 metric tons CO₂ per annum

- Custom industrial plants

- Engineered to order

- ~30–36 months delivery time

- Customized footprint

- Using bulk materials – cost-efficient

- For new and existing industry plants